Welcome to the world of modern manufacturing, where efficiency and productivity are key factors in success. In today’s fast-paced industry, the role of an ERP production system is more important than ever. This system helps companies streamline their manufacturing processes, monitor performance, and make data-driven decisions to optimize their operations. By integrating all aspects of production into one cohesive platform, ERP production systems have become essential tools for manufacturers looking to stay competitive in the market.

Implementing an ERP Production System

Implementing an ERP Production System can be a daunting task for many businesses, as it involves integrating various processes, systems, and departments into one centralized system. However, with careful planning and execution, the benefits of implementing an ERP system can far outweigh the challenges.

One of the first steps in implementing an ERP Production System is to assess the current state of your business processes. This involves taking stock of all the different systems, software, and processes that are currently in place and identifying areas where improvements can be made. This step is crucial in order to understand the specific needs and requirements of your business, as well as to identify any potential roadblocks or challenges that may arise during the implementation process.

Once you have a clear understanding of your current business processes, the next step is to choose the right ERP system for your business. There are many different ERP systems available on the market, each with its own set of features, benefits, and drawbacks. It is important to research and compare different ERP systems to find the one that best aligns with your business goals and objectives.

After selecting the right ERP system, the next step is to plan the implementation process. This involves creating a detailed project plan that outlines the goals, timelines, and resources required for the implementation. It is important to involve key stakeholders from different departments in the planning process to ensure that everyone is on the same page and that all requirements are met.

Once the project plan is in place, the next step is to begin the implementation process. This involves configuring the ERP system to meet the specific needs of your business, migrating data from existing systems, and training employees on how to use the new system. It is important to carefully monitor the implementation process and make any necessary adjustments along the way to ensure a smooth transition from the old systems to the new ERP system.

After the implementation is complete, it is important to continuously monitor and evaluate the system to ensure that it is meeting the needs of your business. This involves tracking key performance indicators, gathering feedback from employees, and making any necessary adjustments or improvements to the system. By continuously monitoring and optimizing the ERP system, your business can ensure that it remains an effective tool for managing production processes and driving business growth.

Benefits of an ERP Production System

Implementing an ERP production system can bring a wide array of benefits to a company. One of the key advantages is improved efficiency in production processes. By streamlining operations and providing real-time data access, an ERP system can help manufacturers optimize their production schedules, reduce lead times, and minimize waste. This increased efficiency can lead to cost savings and improved profitability for the company. Additionally, with better visibility into the production process, businesses can make more informed decisions and respond quickly to changes in demand or supply.

Another significant benefit of an ERP production system is enhanced inventory management. With accurate and up-to-date information on inventory levels, manufacturers can maintain optimal stock levels, reduce excess inventory, and minimize stockouts. This can improve cash flow, reduce carrying costs, and prevent costly production delays. Integrated inventory management in an ERP system can also help businesses track materials, components, and finished goods across the supply chain, ensuring seamless production planning and fulfillment.

Furthermore, an ERP production system can improve quality control processes within a manufacturing facility. By centralizing data on product specifications, inspection criteria, and quality standards, businesses can ensure consistent product quality and compliance with regulations. Real-time monitoring and analytics capabilities in an ERP system enable manufacturers to identify trends, detect defects, and implement corrective actions promptly. This proactive approach to quality control can enhance customer satisfaction, build brand reputation, and drive repeat business.

In addition to efficiency, inventory management, and quality control, an ERP production system can also facilitate better communication and collaboration among departments and stakeholders. By integrating production data with other business functions such as sales, finance, and supply chain, an ERP system enables seamless coordination and information sharing. This cross-functional visibility and transparency can foster teamwork, improve decision-making, and enhance overall organizational performance. With a centralized platform for data exchange and communication, employees can access critical information anytime, anywhere, promoting agility and responsiveness in a fast-paced manufacturing environment.

Overall, the benefits of an ERP production system are manifold, ranging from operational excellence and cost savings to better decision-making and customer satisfaction. By investing in an ERP system tailored to their specific production needs, manufacturers can gain a competitive edge, adapt to market dynamics, and achieve sustainable growth in the long run.

Key Features of an ERP Production System

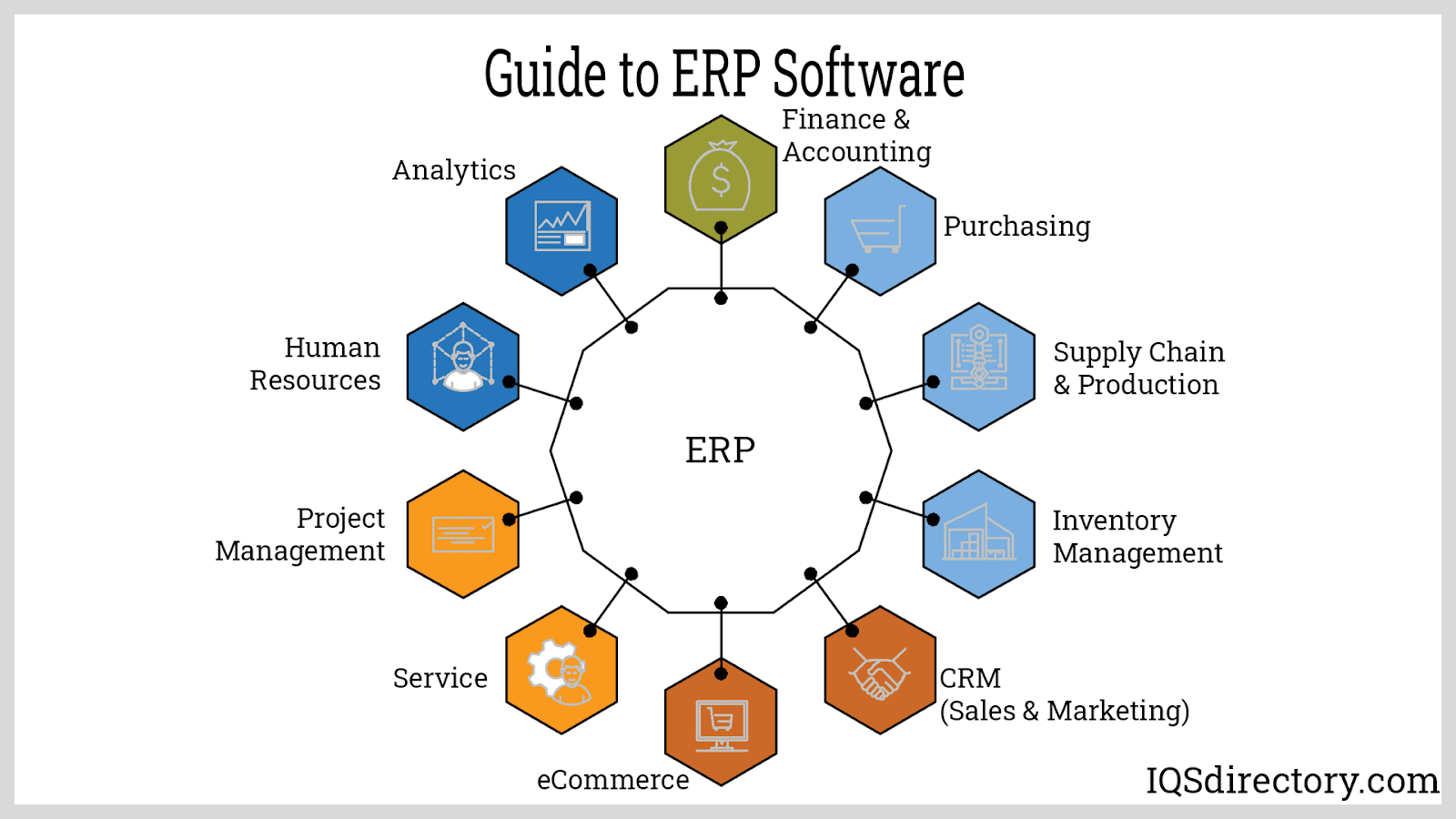

ERP (Enterprise Resource Planning) systems have become essential tools for companies looking to streamline their production processes. These systems are designed to integrate all aspects of a company’s operations into a single, centralized database, providing real-time visibility and control over every aspect of the production process. Here are some key features of an ERP production system:

1. Inventory Management: One of the most important features of an ERP production system is its ability to manage inventory efficiently. The system keeps track of all raw materials, work-in-progress inventory, and finished goods, allowing companies to optimize their inventory levels and minimize stockouts. With real-time updates on inventory levels, companies can make informed decisions about purchasing, production scheduling, and order fulfillment.

2. Production Planning and Scheduling: Another key feature of an ERP production system is its capability to streamline production planning and scheduling. The system allows companies to create detailed production schedules based on factors such as available resources, machine capacity, and customer demand. By automating the scheduling process, companies can reduce lead times, improve on-time delivery performance, and enhance overall production efficiency.

3. Quality Control and Compliance: In addition to managing inventory and production scheduling, ERP production systems also help companies maintain quality control standards and comply with industry regulations. These systems can track quality metrics at every stage of the production process, identify potential defects or issues, and trigger alerts for corrective action. Furthermore, ERP systems can be configured to ensure compliance with industry standards, safety regulations, and quality certifications, helping companies avoid costly fines and reputational damage.

Overall, an ERP production system offers a comprehensive solution for companies looking to optimize their production processes and improve operational efficiency. By integrating inventory management, production planning, and quality control features into a single system, companies can gain real-time visibility, make data-driven decisions, and stay competitive in today’s fast-paced business environment.

Challenges of Implementing an ERP Production System

Implementing an ERP Production System can be a daunting task for any organization. There are several challenges that companies may face during the implementation process. From budget constraints to resistance from employees, these challenges can make it difficult for businesses to successfully integrate an ERP system into their production process.

One of the main challenges of implementing an ERP Production System is the cost associated with it. ERP systems can be expensive to purchase and implement, especially for small and medium-sized businesses. The initial investment required for an ERP system can be a major barrier for companies looking to streamline their production process and improve efficiency. Additionally, there are ongoing maintenance costs and fees associated with ERP systems that can add to the overall expense.

Another challenge companies face when implementing an ERP Production System is the resistance from employees. Employees may be resistant to change, especially when it comes to new technology and processes. They may feel overwhelmed or worried about their jobs being replaced by automation. It is essential for companies to communicate with their employees and provide training and support throughout the implementation process to address these concerns and ensure a smooth transition.

Integration with existing systems is also a common challenge when implementing an ERP Production System. Many companies already have various systems in place for managing their production process, such as inventory management software or supply chain management tools. Integrating these systems with an ERP system can be complex and time-consuming, requiring careful planning and coordination to ensure that data is transferred accurately and in a timely manner.

Furthermore, data migration can pose a significant challenge during the implementation of an ERP Production System. Companies often have large amounts of data stored in various formats and locations, making it difficult to migrate this data to the new ERP system. Data migration requires careful planning and execution to ensure that data is transferred accurately and securely without any loss of information.

In conclusion, while implementing an ERP Production System offers numerous benefits such as improved efficiency and visibility into the production process, it also comes with several challenges. From budget constraints to resistance from employees, integration with existing systems, and data migration, companies must be prepared to address these challenges to successfully implement an ERP system. By addressing these challenges proactively and working closely with employees and stakeholders, organizations can overcome these obstacles and reap the benefits of an ERP Production System.

Best Practices for Successful Implementation of an ERP Production System

Implementing an ERP production system can be a complex and challenging process for any organization. To ensure a successful implementation, it is important to follow best practices that have been proven to maximize the benefits of the system while minimizing disruptions to operations. Here are five key best practices to consider when implementing an ERP production system:

1. Establish Clear Goals and Objectives: Before starting the implementation process, it is crucial to define clear goals and objectives for the ERP system. This will help align the project team and stakeholders on the expected outcomes and ensure that everyone is working towards the same end goal. By defining clear goals and objectives, organizations can better prioritize tasks and allocate resources effectively throughout the implementation process.

2. Engage Key Stakeholders: Involving key stakeholders throughout the implementation process is essential for garnering their support and ensuring the success of the ERP production system. Stakeholders, including senior management, department heads, and end-users, should be actively engaged in the planning, design, and testing phases of the implementation. Their input and feedback will help identify potential issues early on and ensure that the system meets the organization’s needs and expectations.

3. Plan Thoroughly: Proper planning is crucial for the successful implementation of an ERP production system. Organizations should develop a detailed project plan that outlines timelines, milestones, tasks, and responsibilities. It is important to consider potential risks and challenges that may arise during the implementation process and develop contingency plans to address them. By planning thoroughly, organizations can minimize disruptions to operations and ensure a smooth transition to the new system.

4. Provide Adequate Training and Support: Training and support are essential for ensuring that end-users are comfortable and proficient in using the ERP production system. Organizations should provide comprehensive training programs for all users, including employees, managers, and IT staff, to ensure that they understand how to effectively use the system. Additionally, organizations should offer ongoing support and resources to help end-users troubleshoot issues and maximize the benefits of the system.

5. Monitor and Evaluate Performance: Once the ERP production system is implemented, it is important to monitor and evaluate its performance regularly. Organizations should establish key performance indicators (KPIs) to measure the system’s effectiveness in achieving the goals and objectives set during the planning phase. By monitoring performance metrics, organizations can identify areas for improvement and make necessary adjustments to optimize the system’s performance and maximize its benefits.

By following these best practices, organizations can increase the likelihood of a successful implementation of an ERP production system and maximize the benefits it can provide to their operations.

Originally posted 2025-02-18 06:00:00.